- Road construction and maintenance: Bitumen emulsion is used to make cold mix asphalt and slurry seals.

- Soil stabilization: Bitumen emulsion is used to stabilize soils that are prone to erosion or landslides.

- Waterproofing: Bitumen emulsion is used to waterproof roofs, basements, and other structures.

- Industrial applications: Bitumen emulsion is used for grouting, coating metal surfaces, and making asphalt roofing materials.

Bitumen emulsion is a type of bitumen that has been dispersed in water. It is a colloidal suspension, which means that the bitumen droplets are evenly distributed throughout the water. Bitumen emulsions are typically used in cold weather applications, as they do not require heating.

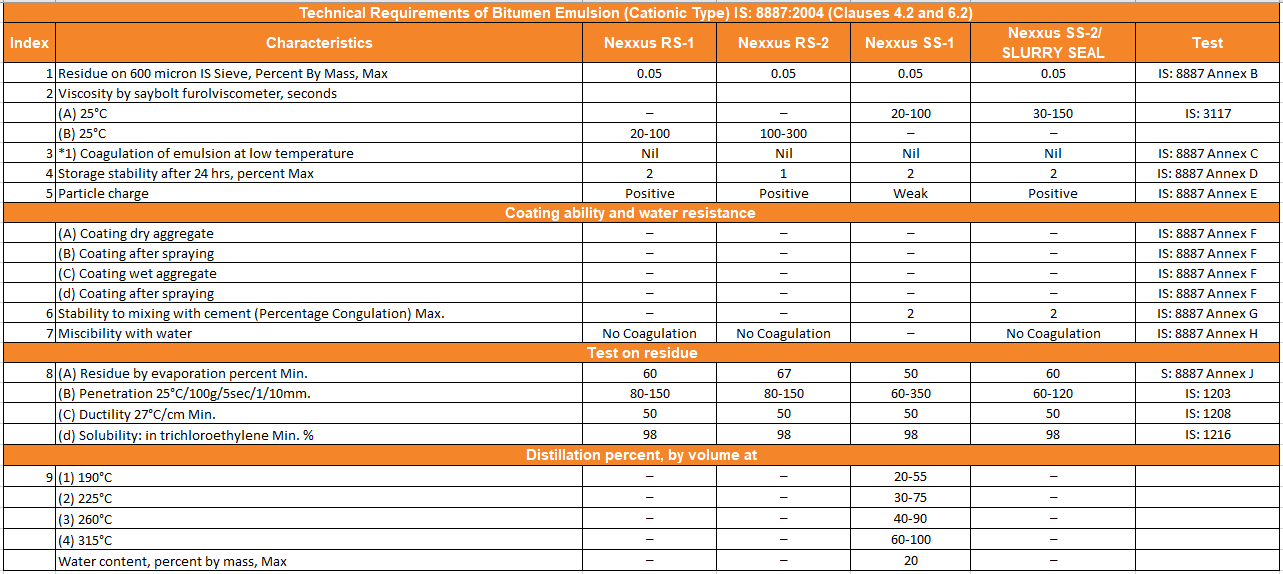

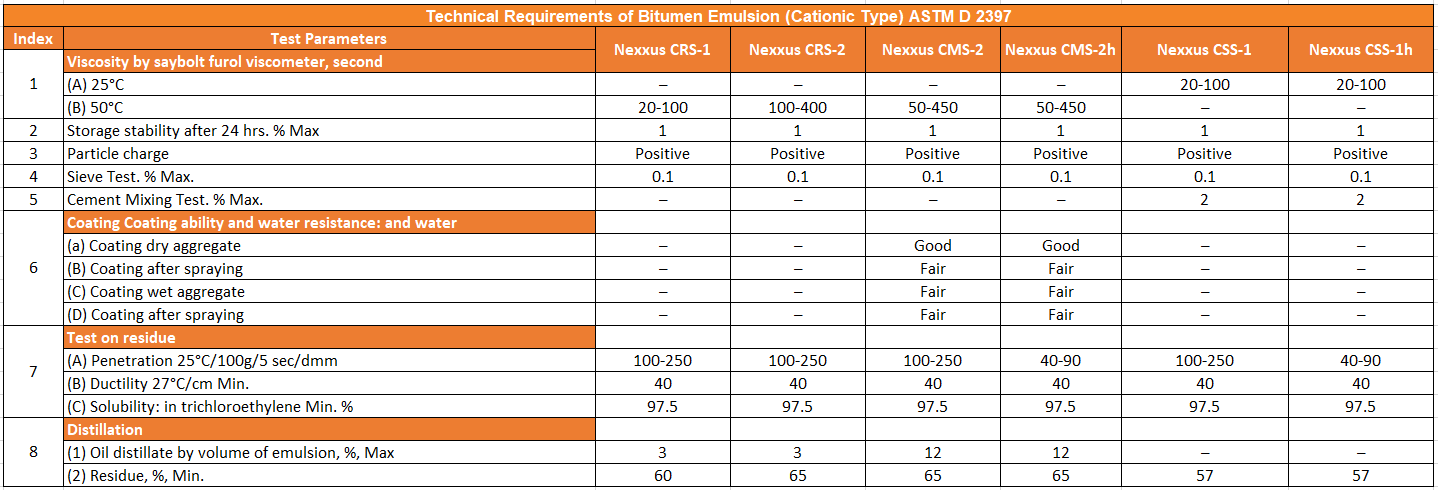

There are two main types of bitumen emulsion: cationic and anionic. Cationic emulsions are used in most road construction applications, as they are more resistant to water. Anionic emulsions are used in some industrial applications, as they have better adhesive properties.

Bitumen emulsion has several advantages over hot bitumen, including:

- Can be applied at room temperature, which makes it a good choice for cold weather applications.

- Relatively environmentally friendly, as it does not produce as many emissions as hot bitumen.

- More flexible than hot bitumen, which makes it more durable in cold weather conditions.

- Easier to apply than hot bitumen, which can save time and money on construction projects.

Bitumen emulsion has a few disadvantages, including:

- It is not as strong as hot bitumen, so it is not suitable for all applications.

- It can be more expensive than hot bitumen.

- It is not as durable as hot bitumen in hot weather conditions.

Bitumen emulsion is made by mixing bitumen, water, and an emulsifier. The emulsifier is a chemical that helps to keep the bitumen droplets suspended in the water. The mixture is then passed through a colloidal mill, which breaks down the bitumen droplets into a very fine dispersion.

Bitumen emulsion can be applied by a variety of methods, including:

- Spraying

- Rolling

- Spreading

The method of application will depend on the specific application. For example, spraying is typically used for road construction applications, while rolling is typically used for waterproofing applications.

The lifespan of bitumen emulsion will depend on the specific application. In general, bitumen emulsions can last for several years in road construction applications. In waterproofing applications, bitumen emulsions can last for up to 20 years.

Progressive Company

We are progressive company

Certified Products

Laboratory certified Products

Environment Safe

Environment safety certified Products

Stay Connected